Articles

Gold: The Silent Profit Stream Waste Companies Can’t Afford to Ignore

Let me be blunt.

While the world obsesses over rare earths, lithium, and cobalt, there’s a quiet metal fueling every serious industrial strategy on the planet: gold.

Not just for jewelry. Not just for vaults.

Gold is the backbone of high-reliability production—servers, EVs, data centers, semiconductors, aerospace, and defense.

It’s why even companies like Tether, the largest stablecoin operator in the world, are openly stating that gold is a precious asset for the future. If billion-dollar finance firms are betting on gold, shouldn’t you, as a waste operator sitting on gold-bearing scrap, be asking yourself:

“Am I cashing in—or throwing it away?”

Why Gold Matters in Production (and Why It Won’t Stop)

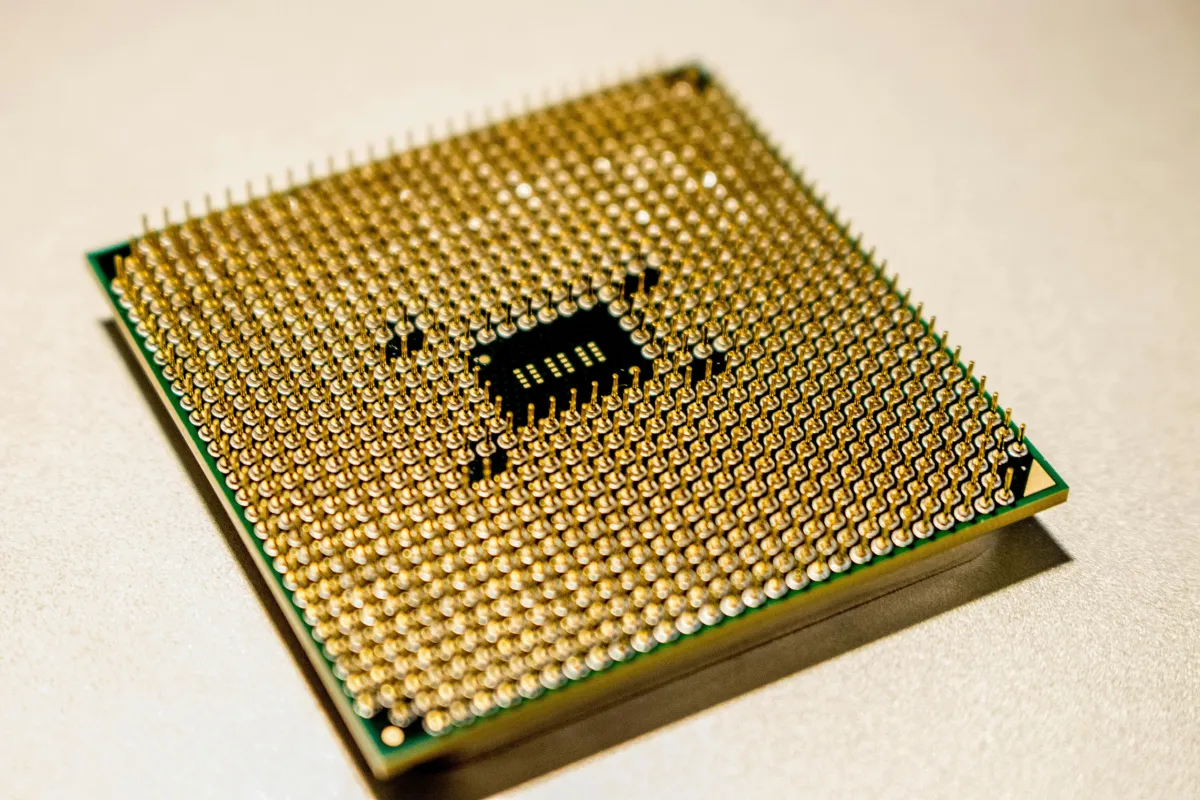

Electronics manufacturers don’t choose gold because it’s glamorous.

They choose it because it doesn’t fail.

Contacts & connectors: ultra-thin gold plating keeps current flowing with zero corrosion.

Bonding wires in semiconductors: still dominant in high-reliability chips.

Critical hardware: EV batteries, aerospace avionics, defense-grade circuits, medical devices.

Smartphones, servers, inverters, chargers, and industrial switchgear all contain milligrams of gold. Multiply that by billions of units—suddenly you’re looking at tonnes of demand every single year.

Here’s the kicker: even with substitution efforts (copper bonding, thinner plating), the volume of electronics is growing faster than the thrift. Which means tech-gold demand climbs whether you like it or not.

The 5-Year Forecast: What’s Coming

Let’s cut the noise and focus on what you can act on:

AI Data Centers: Every rack, every switch, every accelerator = gold-plated connectors. Data center growth is exploding in the U.S., Europe, China, and the Middle East.

EVs & Charging: Millions of new connectors, BMS, and inverters. That’s all gold in micro layers.

Grid Upgrades: Europe, Dubai, China, and U.S. states like California and Texas are pouring money into electrification. Reliability means gold.

Hydrogen Economy: Smaller niche, but gold-based catalysts are taking off for purification and electrochemical processes.

Baseline tech demand for gold in 2024 sat at ~326 tonnes. By 2030, we’re looking at 350–400 tonnes annually depending on how aggressive AI, EV, and grid infrastructure scale.

That’s a steady climb. And it won’t be satisfied by mining alone.

Where Waste Management Fits In

This is where you, as a waste company owner, step in.

You’re already handling the urban mine:

Servers and telecom racks being decommissioned.

EV and charging components being upgraded.

Aerospace, defense, and industrial boards scrapped.

Consumer electronics dumped in your flow.

Most operators throw it into the mixed e-waste pile and sell it off for pennies on the dollar. But the smart ones? The ones who know where the gold hides? They’re pulling out double or triple margins by doing one thing: segregating high-value streams at the source.

Action Steps to Capture the Gold Stream

Identify the high-grade fractions.

Stop looking at “all e-waste” the same. Server boards, telecom backplanes, RF components, and EV electronics have thicker gold plating than consumer junk. Prioritize those.Train your team.

A simple workshop to help operators recognize gold-bearing boards or connectors can mean the difference between selling mixed scrap at $2/kg vs. selling segregated lots at $15–20/kg.Partner with refiners who pay on assay, not weight.

Don’t dump into middleman networks that buy by “e-waste kilo.” Build direct relationships with refiners or smelters who pay you on the actual recovered gold content.Leverage timing.

The gold market is volatile. Finance-driven moves (like ETF flows or central bank buys) can spike price. Having segregated gold-bearing scrap ready to sell lets you capture premiums when markets are hot.Think “Gold-Grade” services.

Position yourself not just as a waste collector but as a reliable supplier of secondary gold to local manufacturers. Tariffs and geopolitical risk are pushing companies to domestic sourcing. You can be their bridge.

What This Means for You

The big boys—Tether, central banks, AI data giants—are already securing their gold strategies.

Meanwhile, thousands of waste operators are literally throwing away their cut of the action.

If you want to build resilience in your business and stop leaving money in the landfill, here’s the truth:

Gold recovery from waste is not optional anymore. It’s the survival play.

Your Next Move

I’ll make it easy.

👉 Book a Gold-Grade Waste Audit with me.

In 45 minutes, we’ll:

Map your waste streams.

Pinpoint your hidden gold-bearing fractions.

Estimate your recoverable grams per tonne.

Hand you a playbook on whether to sell now or stockpile.

No fluff. No theory. Just real numbers tied to real profit.

📅 Click here and book your audit now

Because in the next 5 years, gold won’t just be a luxury—it’ll be the currency of reliability. And if you’re not pulling it out of your waste, someone else is.

To Your Success,

Sam Barrili

The Waste Management Alchemist

Sam Barrili

I'm known as the go-to guy for talking about business strategies and growth strategies for waste management companies.

I started my journey in this field in 2009 when I finished my degree in Toxicological Chemistry and joined a wastewater treatment company to develop its market.

Since then, I helped dozens of waste management companies in America and Europe increase their annual profits by over 25 million dollars thanks to my SAM Method.

If you want to know if I'm a good fit for you, read an article or watch a video.

If you find it helpful, I’m probably a good match.

If not, that's OK too.

Call +1 (801) 804-5730

Email: [email protected]